2000 Buddy Davis 78 Enclosed Sport Fisherman

2000 Buddy Davis 78 Enclosed Sport Fisherman

Description

This BUDDY DAVIS 78’ Sportfish, Motor Yacht EPIC lives up to her name. Built for a discerning sport fisherman with a flair for extended cruising. Back in 2000 before many custom builders and production boat builders were building sportfishing boats this large, EPIC was a special project and a sight to be seen. In today’s market, this 2000 BUDDY DAVIS 78’ SPORTFISH represents U.S. custom boat quality, a huge fishing and travel platform, and great value.

She has 4 staterooms with 5 heads. You can comfortably sleep 8 people aboard with 2 separate crew. Built from Buddy Davis with the ability to cross the Atlantic via the Azores’ on her own bottom. Reinforced hull with added stringers and 3,000 gallons of fuel for a range of 2,000 nautical miles without extended fuel bladders. Features like stabilizers, a full width staircase to the bridge and a day head accessible from outside set this boat apart from other sportfish boats of her size. She is as equally comfortable going out fishing for the day as being used either in the Mediterranean or Caribbean Sea!

EPIC is part of a larger fleet of privately-owned yachts where she is professionally cared for. This BUDDY DAVIS 78’ SPORTFISH has a full-time captain. She is well cared for and consistently upgraded. EPIC has an impressive travel resume. She has spent some time in the Mediterranean and would be a great fit fishing or cruising in any of the world’s oceans.

Specifications

Year:2000

Length:78′

Engine/Fuel Type:Twin / diesel

Located In:Fort Lauderdale, FL

Hull Material:Fiberglass

Price

- Current Price: US$ 1,249,000

- Not for sale to US residents while in US waters

Media

Additional Specs, Equipment and Information

Additional Specs, Equipment and Information:

Boat Name: EPIC

Specs

Builder: Buddy Davis

Designer: Buddy Davis

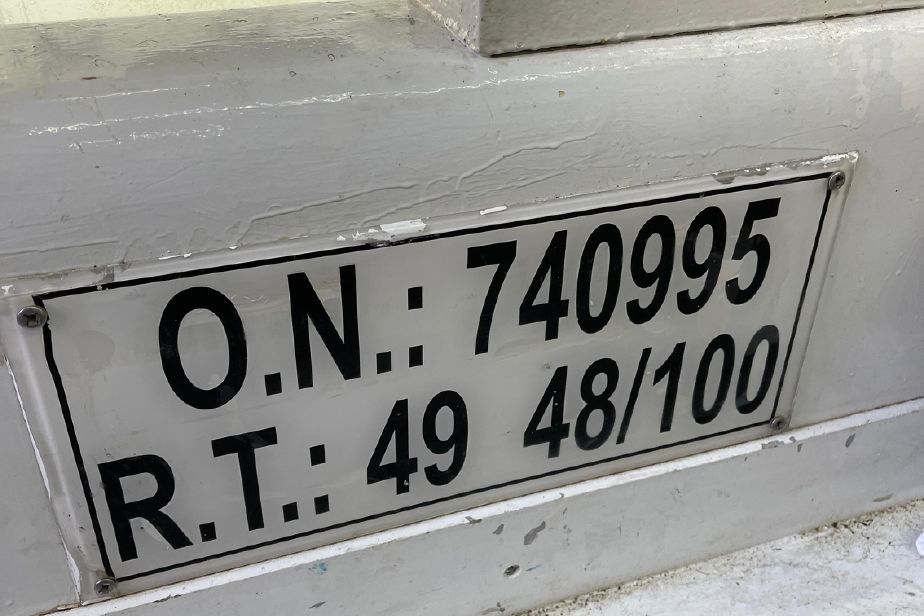

Flag of Registry: British Virgin Islands

Hull Shape: Deep Vee

Dimensions

LOA: 78 ft 0 in

Beam: 19 ft 6 in

Maximum Draft: 5 ft 8 in

Displacement: 98960 lbs Dry Load

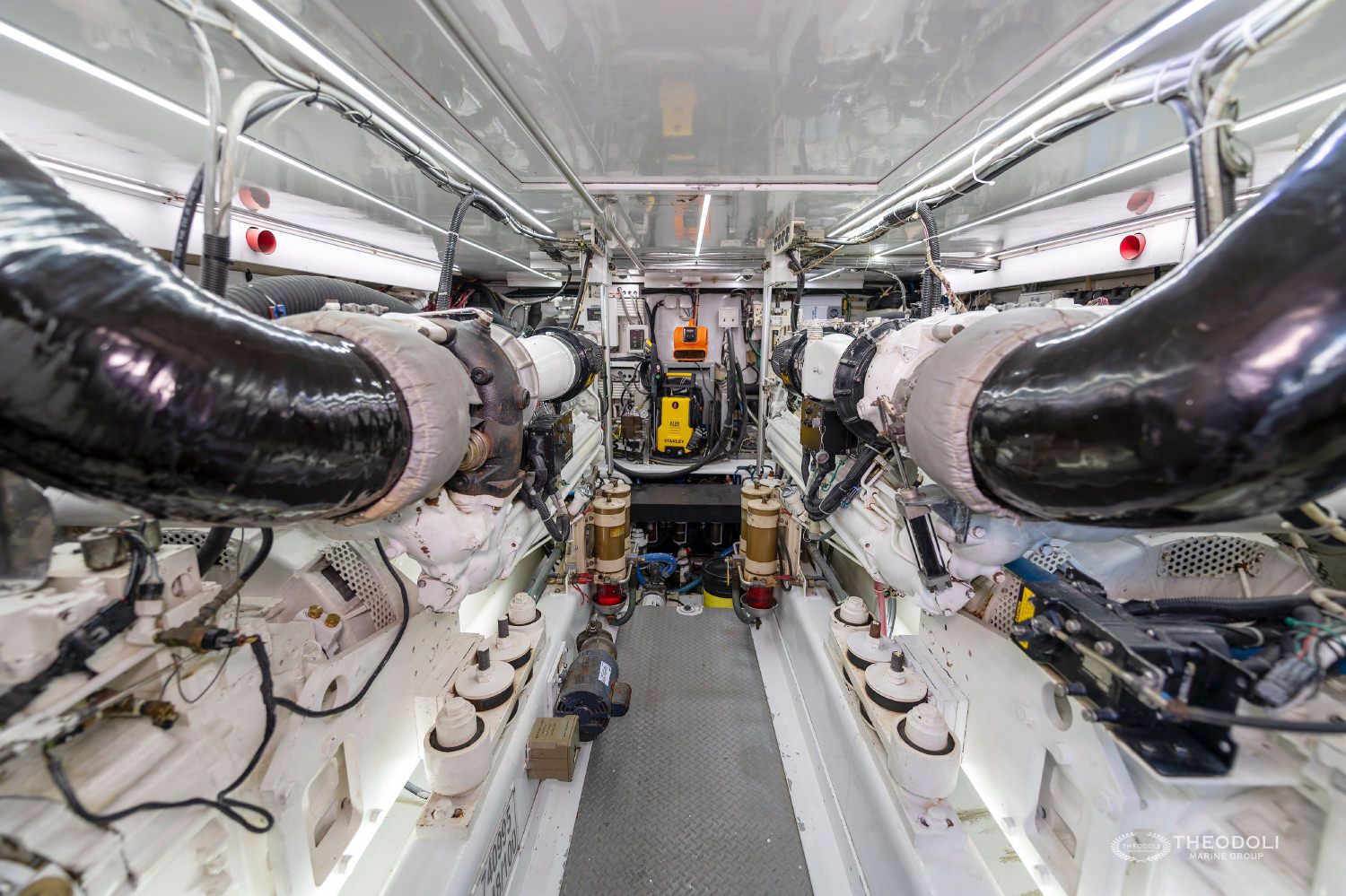

Engines

Total Power: 3600 HP

Engine 1:

Engine Brand: Detroit Diesel

Engine Model: 16V2000

Engine Type: Inboard

Engine/Fuel Type: Diesel

Location: Port

Engine Hours: 5300

Drive Type: Direct Drive

Engine Power: 1800 HP

Engine 2:

Engine Brand: Detroit Diesel

Engine Model: 16V2000

Engine Type: Inboard

Engine/Fuel Type: Diesel

Location: Starboard

Engine Hours: 5300

Drive Type: Direct Drive

Engine Power: 1800 HP

Cruising Speed: 22 knots

Maximum Speed: 28 knots

Tanks

Fresh Water Tanks: 1 (528 Gallons)

Fuel Tanks: 1 (3000 Gallons)

Holding Tanks: 1 (75 Gallons)

Accommodations

Number of single berths: 1

Number of double berths: 3

Number of cabins: 4

Number of heads: 5

Electronics

Depthsounder

Log-speedometer

Navigation center

Plotter

Autopilot

Compass

GPS

VHF

Radar

Computer

TV set

Radio

CD player

Cockpit speakers

Inside Equipment

Stern thruster

Bow thruster

Electric bilge pump

Manual bilge pump

Battery charger

Air conditioning

Hot water

Fresh water maker

Sea water pump

Washing machine

Microwave oven

Electric head

Refrigerator

Deep freezer

Electrical Equipment

Shore power inlet

2 x Generators

Inverter

Outside Equipment/Extras

Teak cockpit

Teak sidedecks

Cockpit cushions

Cockpit table

Swimming ladder

Davits

Tender

Liferaft

Electric windlass

WALKTHROUGH

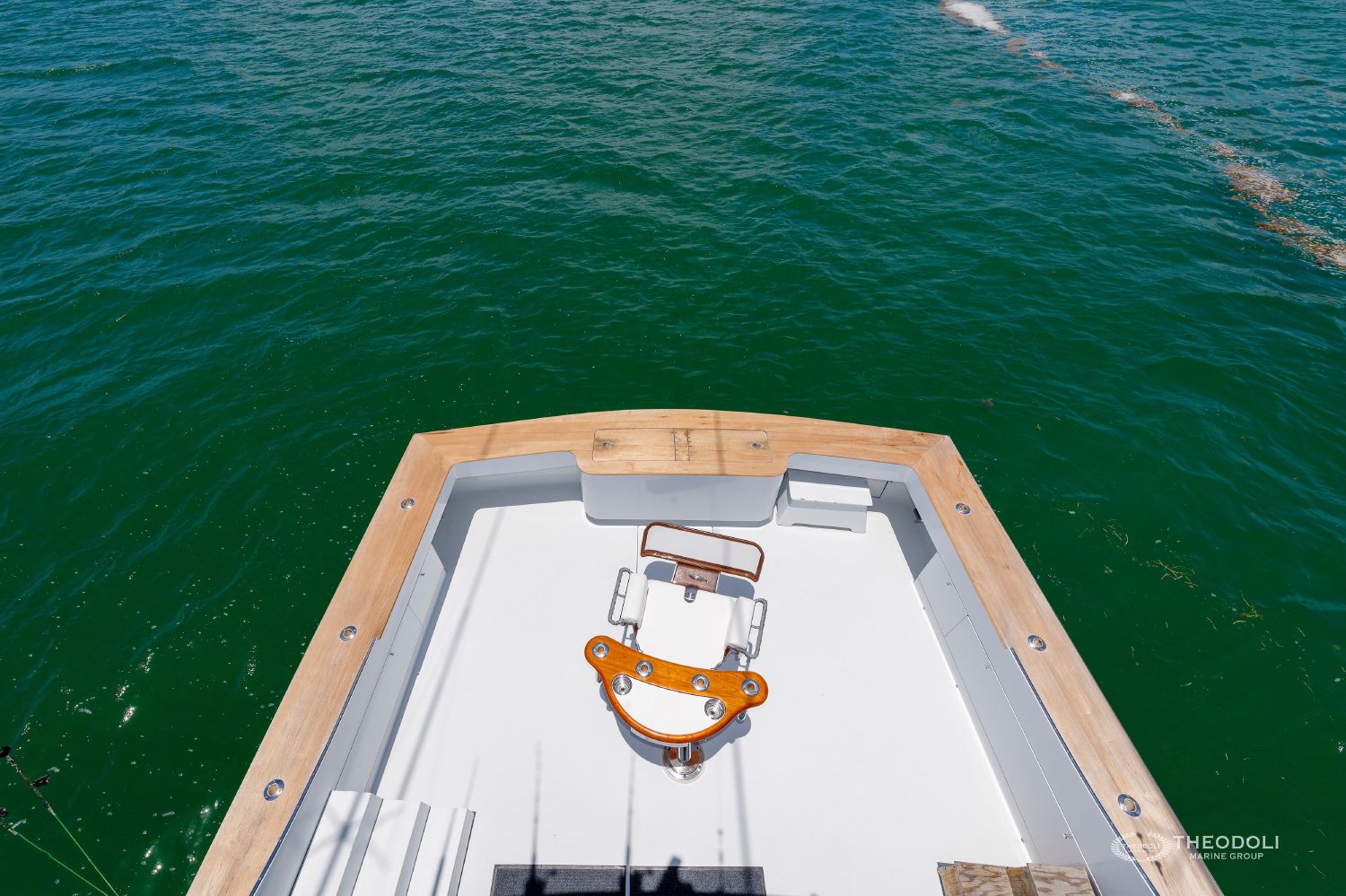

The cockpit and raised mezzanine area onboard “EPIC” is large and impressively laid out. It has features that lend itself well to both the tournament fisherman and the cruising family. These features include…….

- Large fishing cockpit with painted non skid

- Murray brothers fighting chair with offset pedestal, 4 rod rocket launcher back with bait prep tray, 2 drink holders and a

- small tackle drawer

- Teak covering boards

- Stern fish box

- Livewell

- Refrigerated drink box

- Oversized tuna door

- Rod storage under gunwales

Three small steps up from the cockpit brings you to the mezzanine area. This raised perch offers a great view of the cockpit and fishing activities. It also doubles a nice spot to hang while underway and a dockside social area. Other highlights include:

- Molded seating to port with a large freezer underneath

- Fresh water misting system to stay cool

- Day head to stbd with shower

- Aft deck control station

- Custom aluminum safety rails with three rod holders on either side

- Engine room access under the stairs

- Accent lighting

- Music speakers

- Cockpit camera

- High gloss teak door

Standing on the mezzanine you enter the main salon through the brand new high gloss teak door. This main level incorporates the salon, galley, and dinette in a familiar, social, sportfish layout. Immediately upon entering there is a set of spiral stairs that lead up to the weather protected, climate controlled enclosed flybridge. To port is an L shaped sofa with storage underneath and a hi/lo coffee table. The sole is sculpted carpet with a runner on top. The woodwork is impressively done in satin finished teak.

There are AV components and storage in the starboard side cabinets with a large flatscreen TV. After the current owner purchased her, all of the countertops were updated to granite and some other customizations ordered. A custom athwartships bar top was added just below the galley countertops on the salon side. This has additional storage cabinets underneath and two custom bar stools.

One small step up leads us to the dinette and galley. The sole of this area is now a high gloss teak and holly. To port, enclosed in a teak cabinet with granite top is a Scottsman ice maker. Just fwd of that to port is a L shaped dinette and granite table top.

To starboard is a galley equipped to satisfy the hungriest of fishing crews. Her features include:

- Custom granite countertop with a sea edge

- 5 burner GE ceramic cook top

- Dual basin stainless steel sink

- Wine chiller

- Sub zero fridge and freezer drawers

- Whirlpool trash compactor

- Whirlpool microwave oven

- Excellent storage including large cabinet for pots and pans

Just forward of the galley is a large multi-purpose room that doubles as a huge walk in storage room and a crew stateroom. She is outfitted with:

- Oversize stand up freezer

- Combo washer/Dryer

- Second wine chiller

- Breaker panel

- Storage drawers

- Bunk Beds

- Hanging locker

- Flat screen TV, DVD and SAT receiver

- Air conditioning

All the way forward on the port side of the main deck is a stairwell that descends to the lower accommodations. Once below the wood tone changes to a lighter tone honey maple with burlewood trim and drawer faces. It is a nice contrast to the darker teak up top and gives it a more open spacious feel. The four stateroom four head layout is well done.

Once below the wood tone changes to a lighter tone honey maple with burlewood trim and drawer faces. It is a nice contrast to the darker teak up top and gives it a more open spacious feel. The four stateroom four head layout is well done.

Once below, just to port is a full head open to the hallway with a second private entrance from the portside bunk room.

Port Stateroom

- Fixed lower berth

- Storage drawers underneath berth

- Hanging locker

- Drop down Pullman berth to create bunk beds

- Private access to shared head Climate controls

Starboard Guest Stateroom

- Full size berth against outside wall

- Hanging locker

- Flatscreen TV, DVD and SAT –

- Storage cabinets above bed

- Climate controls

- En suite head with tile floor, stall shower, headhunter toilet, porcelain sink, solid surface countertop, beveled glass mirror/medicine cabinet, storage and textured wall coverings

Forward VIP Stateroom

- Island queen berth

- Outboard storage cabinets

- Dual hanging lockers

- Flatscreen TV, DVD and SAT

- Climate controls

- Bomar hatch to foredeck

- En suite head with tile floor, stall shower, headhunter toilet, porcelain sink, solid surface counter top, beveled glass mirror/medicine cabinet, storage and textured wall coverings

Master Stateroom

The master stateroom is aft and lives up to her master billing. Some of her highlights include:

- Island master berth

- Custom padded fabric head board

- Mirror ceiling panel above the bed

- (3) hanging lockers

- Hullside window for natural light

- Tons of storage

- Honey maple wood with burle drawer fronts and cabinets

- Large Samsung flatscreen TV with DVD and SAT

- His and her master head with large center line shared tile shower, dual headhunter toilets, porcelain sinks on either side, solid surface countertops, beveled glass mirrors/medicine cabinets, storage and textured wall covering

Enclosed Flybridge and Skylounge

- L shaped leather sofa to port

- Custom granite table

- Starboard side custom granite countertop with storage and U line refrigerator beneath Centerline STIDD Hi back Admirals model helm chair with matching double STIDD companion seats to port and stbd

- Aft bulkhead window opens up to flybridge mezzanine seating

- Outside set of full controls for backing down on that tournament winning marlin

- Centerline ladder up to tower station

Helm and Electronics

- (2) large Northstar 6100i units for chartplotter, depth sounder and primary radar functions

- Back up commercial grade Furuno 72 mi radar

- Furuno depth sounder and fish finder

- Furuno RD 30 speed, temp and depth

- Detroit diesel electronic controls and gauges

- Simrad auto pilot

- ABT hydraulic bow thruster

- Niad hydraulic stabilizers

- (2) ACR spotlights

- (1) ICOM

- (1) Standard VHF radio

Tower electronics

- Large Northstar 6100i

- DD electronic controls and gauges

- Simrad auto pilot

- ACR spotlight controls

- Furuno RD 30

- Icom VHF

EXCLUSIONS

- Owner’s personal effects, fishing gear and tools are excluded from the sale.

BUDDY DAVIS 78

Buddy Davis was a young charter captain some 25 years ago when he started working in the off season alongside local builders on North Carolina’s treacherous Outer Banks. He already knew that any vessel going to sea in these deadly waters must contend with vicious rips and currents, plough through chaotic walls of water that sometimes tumble into the Carolina inlets, and be built to stay high, dry and sturdy if paying guests were to come back as repeat customers.

You could say he had a flair for flare, a talent that more than any other feature typifies the mature Davis style and could be seen with dramatic effect when the Davis 78′ Sportfisherman. Viewed from dead ahead at water line level this was a shape that looked more like a flared vase than a conventional sportfish yacht.

It is a design from a man enlightened by the wisdom that comes only from hard experience in heavy seas. Quality in all worthwhile manmade objects and particularly in boat building always means top dollar, because quality demands the best design, construction, materials, equipment and craftsmen. Any get-rich-quick builder can throw a load of inferior installations and equipment into the mix but in the long term it makes little sense for an owner who cares about performance and, in the longer term, the boat’s resale value.

What you get in the Davis 78 is an ocean-going yacht designed and build to provide comfort, reliability and optimal performance for big game fishermen who want luxury and a stable fighting platform in the same hull.

On this yacht the benefits start in the capacious cockpit, which is free of clutter, has abundant refrigerated and gear storage, and features and International fighting chair (with rocket launcher!), flush-mounted Rupp rod holders in coaming boards, live well with macerator, icemaker, salt and freshwater washdowns, four-drawer tackle center, bait preparation counter, phone and power outlets, all contained within a handsome and teak covering boards over teak coaming. Steps from here lead to a mezzanine deck above and forward of the cockpit; it has a head/shower to starboard, swing safety gates to port and starboard, and a freezer under bench seating on the portside. Entry to the enclosed salon is via a starboard door on the mezzanine.

This reveals an interior that’s far removed in concept and atmosphere from the gladiatorial arena that partly defines a sportfish cockpit. Here we find elegance and comfort, climate controls, supple leather upholstery, a large bar with wine cooler, entertainment centerand, one step up from the salon dinette. The adjacent full-service galley has a four-burner cook top, microwave oven, four refrigerated Sub Zero drawers and lockers; galley flooring and countertops are polished granite.

There is a utility room forward of a galley area; this also serves as a pantry and contains a 12-cubic foot industrial grade stainless steel freezer, storage lockers and drawers, washer/dryer and the main electrical breaker panel. A door to starboard leads to the mate’s double-berth cabin, which has storage drawers under the bunk, a hanging locker, audio/visual center and head.

Owner and guest accommodation is reached by a companionway leading forward and down from the salon deck. The full-beam master suite is midships and two steps below the guest staterooms. It features a mirror above the queen size bed. The master bathroom features a head, large shower and twin marble sinks.

Both guest staterooms, one to starboard and a VIP suite forward, have queen beds, entertainment centers, private heads with show stalls and granite-topped vanities. The captain’s cabin below midships on the port side has a double berth, audio/video system, and access to a head/shower.

A spiral staircase leads from the salon to an enclosed wheelhouse/lounge. The same quality of finish throughout the interior is found in the lounge, where there is an entertainment center with a satellite TV receiver on a retractable hydraulic lift. A door leads from the lounge to the outside helm station and an observation.

It was from the tuna tower helm position that the captain gave his orders to depart for a sea trial. As we headed for the channel to the open sea we realized that there was a strange silence at this elevated height. Our twin 1800 HP diesels were inaudible; not only that, the absence of vibration made us doubt that we were actually underway.

We met five-foot seas in open water but the Davis-designed bottom neutralized these and we were soon gliding comfortably at a cruising speed of 25 knots across the surface, so comfortably in fact that it seemed to make little difference whether we ran with or against the seas, which is an indication of the design strength of the deep, narrow entry.

All things considered, the Davis 78 is a true luxury yacht in furnishing and fixtures, and one that seems untroubled by hard going. There can be little doubt that she will attract an exclusive following among shrewd buyers who appreciate the value of quality, comfort, performance and durability.

HULL

The hull and superstructure were painted with Awlgrip in 2009. There was a large stainless steel portlight installed in the master stateroom for natural light and ventilation. The transom is a beautiful varnished teak veneer.

MECHANICAL / ELECTRIC

– MTU 16v2000 M90 (W4 just completed on both main engines)

– Racor 75/1000 Max fuel filters for main engines

– Racor 500MA fuel filters for generators

– Twin Disc gearboxes

– American 32 hp bow thruster

– 2 X Seaward 20 gallon water heaters

– Walvac central cleaning system

– Octomarine compact direct-plumb softwater system (2010)

– WaterMaker, Inc. 1,100 gpd watermaker

– Naiad stabilizers

– Cruiseair air conditioning system

ELECTRIC

– 2 X Northern Lights 32 kW generators (Recent full service completed.)

– 2 X Sentry 24v 50 amp battery chargers

– 8 X 12v gel/AGM batteries

– ASEA AC-25 3 phase shore power converter unit

– Glendinning remote control cablemaster syste with 60′ 100 amp cable (2010)

– Underwater lights

FISHING EQUIPMENT

– Murray 4 way rocket launcher/fighting chair

– Covering board and cockpit rail rod holders

– Cockpit side covered rod storage

– Outriggers

– Refrigerated stainless steel transom fish box

– Built-in ice box with shaved ice feed

– Built-in live bait well

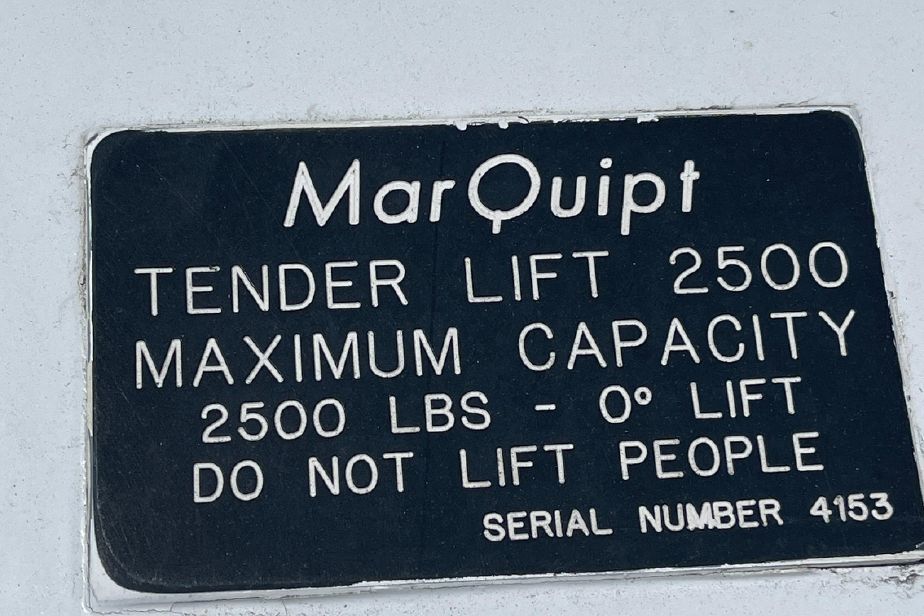

TENDER

– 2019 Brig F420HT, 14ft RIB with Honda 50hp four stroke outboard (10hrs)

– Marquipt 2500 lb tender davit

SAFETY

– 2 X DBC six man life rafts

– ACR Global Fix 406 EPIRB

– McMurdo G5 406 EPIRB

– CO2 engine room fire suppression system

– Lifejackets, flares, medical kit, liferings

MAINTENACE / REFIT LIST

M/Y Epic Significant maintenance list

(Not included are routine items such as zincs, fluids, fuel filters etc)

Main Engines

Jan 2011

Turbo flaps were sticky and freed up. Small fuel leak on stb manifold sealed.

W4 service – Heat exchanger plates cleaned, cylinders borescoped, injectors tested and replaced where spray pattern not sufficient, valve clearance. Oil & filter change, coolant drain and flush.

March 2017

Injector replaced by Motor Services Hugo Stamp

Heat exchangers cleaned

October 2017

All engine mounts replaced by Motor Services Hugo Stamp

September 2019

Marine interface module replaced on Starboard main engine by RPM Diesel.

December 2019

Oil samples pulled from Mains, Gearboxes and generators. All within Specs.

February 2020

Oil pan gasket replaced on Port. Oil and filters changed. Performed by RPM

March 2020

Master battery replaced on Starboard DDEC module.

2 new DDEC displays installed in tower station.

Scheduled April 2021

MSHS to rectify oil leaks on Mains and gearboxes, clean heat exchangers then sea trial.

Generators

Jan 2011

2400 hrs service on port gen. Rebuild Injection pump, replace injectors, clean heat exchanger etc. Performed by RPM Diesel.

Nov 2011

2400 hrs service on stb gen. Rebuild Injection pump, replace injectors, clean heat exchanger etc. Performed by RPM Diesel.

December 2019

AVR replaced on Starboard Generator after sending power spike through boat

Exhaust System

August 2019.

12 inch mounting ring on port exhaust failed. Vessel hauled, port and starboard risers removed.

Mounting rings removed and mufflers modified to take wider 3 inch mounting rings. All silicone and clamps replaced and system reassembled. Note. Keep a 16 inch ball fender on board just in case.

Fuel tanks

November 2016

All fuel tanks cleaned and fuel polished.

Running Gear

November 2016

Rudders dropped, seals and bearings replaced. Done by High Seas Yacht Service

September 2017

Shafts checked for straightness, props checked for balancing. Cutlass bearings replaced. Done by High Seas Yacht Service at LMC.

August 2019

Engine and running gear alignment checked again by High Seas Yacht service

March/April 2021

Currently in progress

Propellors removed and tuned to class s.

Shafts and rudders removed . all bearings and bushings replaced. To be reinstalled, realigned and sea trialed. Performed by High Seas Yacht Service

Stabilizers

November 2016

Stabilizers removed and serviced with new seals etc. Rams rebuilt, heat exchanger cleaned. Hoses replaced. Done by high Seas Yacht Service.

February 2021

Hydraulic leak in engine room unit traced to directional valve body. Removed, seals replaced and reinstalled. Performed by crew.

Air conditioning

December 2016

All air handlers and related ducting replaced. General service and tuning of system. Done by Beard Marine

July 2020

Chillers serviced and trac circulated through seawater lines. All engine room chilled water pipe insulation replaced due to sweating. All air handlers serviced. Performed by Beard Marine

December 2020

Installed rule sump system for Chiller condensate drain lines so no longer draining into Engine room bilge. Discharge lines for chillers combined for ease of cleaning and cooling tower hook up. Also to provide Overboard for new sump pump. Performed by crew

Eskimo 600 Ice Maker

Unit removed from vessel and bench tested. Serviced, recharged with weighed amount of gas and reinstalled when repairs completed to damaged sub floor. New level controller installed. Operating well.

Engine room Lighting

Old CFL lights all removed and replaced with 24VDC LED strip lights and channels. 24vdc circuit connected directly. 120vac circuit fed Via step down transformer.

LED lights also installed in FWD crew bilge, under dash in wheelhouse and steering flat.

Wheelhouse Windscreen Wipers

May 2020

All wiper arms replaced with longer arms to improve screen coverage. All blades replaced. Center motor replaced due to heavy rusting. Water damage to wood at mounting point repaired and system recommissioned.

Outriggers

July 2019

Old pipe welders 4 ft hydraulic rams leaking and replaced with Rupp 5 ft rebuilt rams. New mounting collar installed and pivot bushes replaced. All external braided Hydraulic lines replaced.

Bilges and Raw Water plumbing

May 2020

Many raw water strainers removed and relocated. Raw water pumps for fish box and drinks fridge relocated. Raw water hoses replaced due to age. Eskimo

skimo upgraded to ¾ hose. The one unit not ¾ is the drinks fridge, which is 5/8 hose but much smaller unit. March pumps replaced- drinks box (120VAC) and rear fish box (240VAC).

FWD Engine room Rule 3600 bilge pump replaced.

June 2020

Tuna tube pump relocated to improve access to steering components. All hose replaced and distribution manifold cleaned, checked and reinstalled.

Water softener

May 2020

Octomarine water softener removed, stripped, cleaned and tested on the dock. Repalced leaking seals. Reinstalled, recharged and recommissioned.

Steering

July 2020

Tie bar removed from Vessel. Both Ball joints replaced and bar reinstalled. Shortened to maximum with toe in still remaining. Fine tuning to be done at next haul out for accurate measurements

August 2020

New rudder angle indicator installed due to erratic readings. New Robertson AP 20 Autopilot installed in tower station. Dock and sea trials performed. Good operation. Crew

September 2020

Hydraulic ram base mount removed and reversed in order to balance steering geometry. Previously 37 degrees to STBD and 22 to port. Now within 3 degrees each way. Crew

March/April 2021

Rudders dropped and bushings replaced. Toe in checked and tie bar adjusted accordingly. High seas chased slow leak allowing pressure to slowly bleed down.

Ships Air

April 2020

New ships Ultra quiet compressor installed under dash to feed ships horn.

Ships Electric blinds

April 2019

All salon blinds dismantled and restrung. Some failed components replaced. All blinds working.

Performed by crew.

Water maker

June 2020

New electric motor fitted to High Pressure pump, Pump head bench tested by Watermakers, Inc and performing well. Motor capacitors remote mounted and pump/motor assembly relocated under starboard engine bank. Some plumbing relocated and hoses checked.

October 2020

Membranes removed and bench tested By Watermakers, Inc. leaking fittings replaced. All 3 performing well.

CCTV System

All 8 cameras replaced with multi system (analog and digital) cameras with Night vision. Multiplexer replaced also but still Analogue.

UNDERWATER LIGHTS

Work under way

March/April 2021

All three underwater lights and drivers removed and replaced with SeaVision white L.E.D. lights.

TRIM TABS

Work under way

March/April 2021

Troubleshooting system resulted in stripping and replacing majority of components and upgrading to the new Bennett Auto Trim Pro system. 2 actuators replaced and sensor wires added. 2nd Hydraulic power unit added to increase responsiveness of tabs. Port and starboard tabs now have their own HPU, doubling the response time.

Tower, bridge deck aft and main deck aft station controls disabled as new “Auto Pro functions make them obsolete. The Auto trim pro will extend tabs as the boat accelerates to keep the bow down. It will also retract when the boat slows again. It will also adjust tabs to compensate weight shifts at speed. All plumbing replaced and HPUs relocated for easier access/ top up. Visual tab position indicator added to wheel house station.

THROUGH HULLS

March/April 2021

Work under way.

Main engine sea cocks stripped, cleaned, serviced and replaced. Now two finger operation. Completed

All other through hulls replaced. Performed by All Points

BOW THRUSTER

March/April 2021

Work under way

System troubleshooting performed due to lack of performance on bow thruster, but good operation on davit and windlass. Bow thruster pressure operating at below 1000 PSI when should be 2,500 PSI. Problem likely traced to load sensing valve. Test when back in water

BOTTOM PAINT

APRIL 2021

New bottom paint, prop speed and zincs